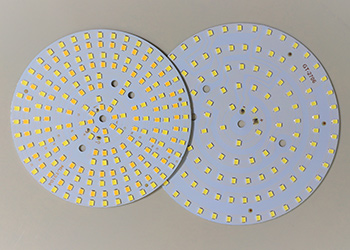

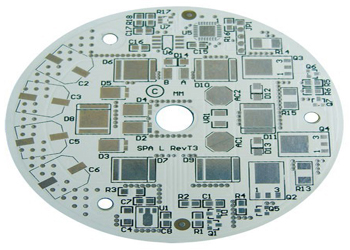

A printed circuit board that uses an aluminium core as its base material is known as an aluminium PCB, often referred to as an aluminum-based PCB or a metal-clad PCB (MCPCB). It is appropriate for applications that call for effective thermal management since it is specially made to give outstanding thermal conductivity and heat dissipation qualities.

The aluminium core, the dielectric layer, and the copper layer make up the three primary layers that make up an aluminium PCB. Normal aluminium alloy is used to create the aluminium core, which serves as a heat sink. As a result of its excellent thermal conductivity, heat can swiftly move throughout the board. The PCB is made more resilient to mechanical stress and vibrations thanks to the aluminium core's mechanical stability and rigidity.